Bessemer Furnace: Revolutionizing The World Of Steel Production

Imagine this: a world where steel production was slow, costly, and inefficient. That’s exactly what the 19th century looked like before the Bessemer furnace came into play. This groundbreaking invention changed the game, making steel production faster, cheaper, and more accessible. Today, we’re diving deep into the fascinating history, mechanics, and impact of the Bessemer furnace, and trust me, it’s a story worth telling. So, buckle up and let’s get started!

Before we dive into the nitty-gritty, let’s set the stage. The Bessemer furnace wasn’t just another industrial machine; it was a revolution. It’s like the iPhone of its time—something that completely transformed an entire industry. Back in the day, steel was a luxury material, reserved only for the wealthy and powerful. But thanks to this furnace, steel became a commodity available to everyone.

Now, you might be wondering, “Why should I care about a 19th-century furnace?” Well, my friend, the Bessemer furnace isn’t just a piece of history; it’s a testament to human ingenuity and innovation. Understanding its significance can give us insights into how far we’ve come and where we’re headed. So, let’s explore the ins and outs of this remarkable invention.

Table of Contents

- The Fascinating History of the Bessemer Furnace

- Biography: Sir Henry Bessemer

- How the Bessemer Furnace Works

- The Impact on the Steel Industry

- Advantages of the Bessemer Process

- Limitations and Challenges

- Modern Applications and Legacy

- Bessemer Furnace vs Other Steelmaking Methods

- Economic Implications

- The Future of Steel Production

The Fascinating History of the Bessemer Furnace

The story of the Bessemer furnace begins in the mid-1800s, a time when the world was on the brink of the Industrial Revolution. In 1856, Sir Henry Bessemer, a British engineer and inventor, unveiled his groundbreaking method of producing steel. This method, known as the Bessemer process, used a special type of furnace to convert molten iron into steel by blowing air through it. The result? Steel that was purer, stronger, and cheaper than ever before.

At the time, the demand for steel was skyrocketing, driven by the need for railways, construction, and machinery. Traditional methods of producing steel were simply not up to the task. They were labor-intensive, time-consuming, and expensive. The Bessemer furnace changed all that, paving the way for the modern steel industry.

Key Milestones in the Development of the Bessemer Furnace

- 1856: Sir Henry Bessemer patents the Bessemer process.

- 1858: The first commercial Bessemer furnace is built in Sheffield, England.

- 1860s: The process spreads across Europe and the United States, revolutionizing steel production globally.

- 1870s: Improvements and modifications are made to the furnace, increasing its efficiency and capacity.

Biography: Sir Henry Bessemer

Sir Henry Bessemer was more than just the inventor of the Bessemer furnace; he was a true innovator who left an indelible mark on the industrial world. Born in 1813 in Hertfordshire, England, Bessemer was a self-taught engineer with a knack for problem-solving. Over his lifetime, he obtained more than 100 patents, covering a wide range of inventions from sugarcane processing machinery to telescopic gun sights.

Below is a quick overview of his life and achievements:

Biographical Data

| Full Name | Sir Henry Bessemer |

|---|---|

| Birthdate | January 19, 1813 |

| Place of Birth | Hertfordshire, England |

| Death | March 15, 1898 |

| Notable Achievements | Inventor of the Bessemer process, holder of over 100 patents |

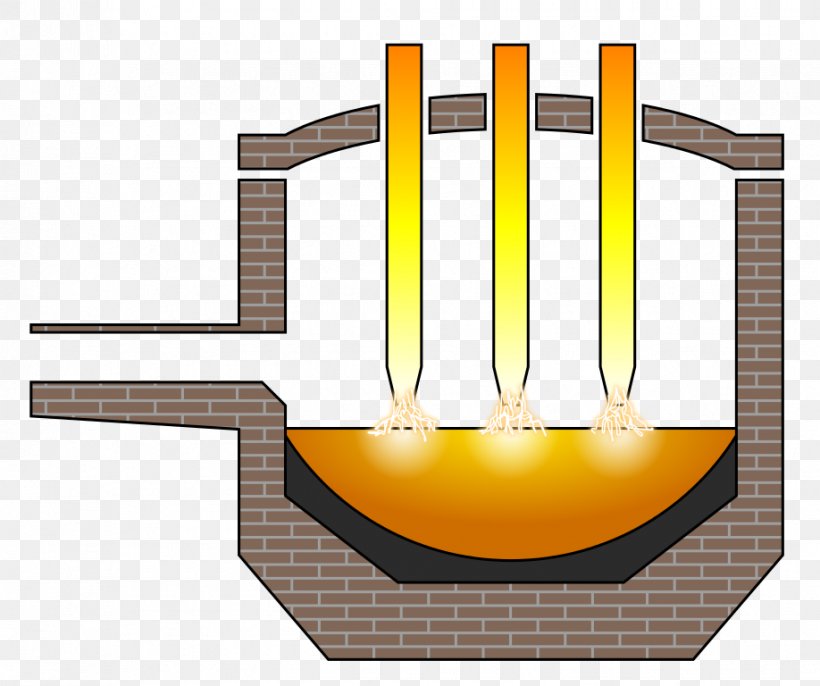

How the Bessemer Furnace Works

Now that we’ve covered the history and the man behind the invention, let’s dive into the mechanics of the Bessemer furnace. At its core, the Bessemer process is all about removing impurities from molten iron to produce high-quality steel. Here’s how it works:

First, molten iron is poured into a large, pear-shaped vessel called a converter. Air is then blown through the molten iron, causing a chemical reaction that oxidizes the carbon and other impurities. This process, known as “blowing,” is what gives the Bessemer furnace its unique name. As the impurities are removed, the molten iron transforms into steel, which can then be poured into molds or further processed.

Key Components of the Bessemer Furnace

- Converter: The main vessel where the molten iron is treated.

- Air Blower: The device that supplies air to the converter.

- Tapping Hole: The outlet through which the steel is poured out.

The Impact on the Steel Industry

The introduction of the Bessemer furnace had a profound impact on the steel industry. Prior to its invention, steel was produced using methods like puddling and cementation, which were slow and expensive. The Bessemer process changed all that, making steel production faster, cheaper, and more efficient. This, in turn, led to a surge in the availability of steel, driving innovations in transportation, construction, and manufacturing.

One of the most significant impacts of the Bessemer furnace was its role in the development of the railway industry. With cheaper and more abundant steel, railways could be built faster and more cost-effectively, paving the way for the expansion of rail networks across the globe.

Statistics on the Growth of Steel Production

- Before the Bessemer process, global steel production was around 300,000 tons per year.

- By the late 1870s, steel production had increased to over 5 million tons annually.

- The cost of steel production dropped by more than 80% thanks to the Bessemer process.

Advantages of the Bessemer Process

The Bessemer process offered several advantages over traditional methods of steel production:

- Speed: The process was much faster than traditional methods, allowing for large-scale production.

- Cost-Effectiveness: The use of air instead of expensive materials like coke made the process cheaper.

- Quality: The steel produced was of high quality, suitable for a wide range of applications.

These advantages made the Bessemer process the go-to method for steel production for several decades.

Limitations and Challenges

Despite its many advantages, the Bessemer process had its limitations. One of the biggest challenges was its inability to handle high-phosphorus iron, which limited its use in certain regions. Additionally, the process required precise control over the blowing time to ensure the right carbon content in the steel.

Over time, these limitations led to the development of newer methods, such as the open-hearth process and the basic oxygen process, which eventually replaced the Bessemer furnace.

Common Issues with the Bessemer Process

- Difficulty in controlling carbon content.

- Inability to handle high-phosphorus iron.

- Environmental concerns due to the release of impurities into the air.

Modern Applications and Legacy

While the Bessemer furnace is no longer in widespread use, its legacy lives on in modern steel production methods. The principles behind the Bessemer process have influenced subsequent innovations, such as the basic oxygen process and electric arc furnaces. Today, steel production is more advanced and environmentally friendly, but the foundations laid by the Bessemer furnace remain relevant.

In addition to its impact on the steel industry, the Bessemer furnace also played a role in shaping modern industrial practices. Its emphasis on efficiency, cost-effectiveness, and innovation continues to inspire engineers and manufacturers around the world.

Bessemer Furnace vs Other Steelmaking Methods

When comparing the Bessemer furnace to other steelmaking methods, it’s important to consider factors like cost, efficiency, and environmental impact. While the Bessemer process was revolutionary in its time, newer methods have surpassed it in many areas.

For example, the open-hearth process, developed in the late 19th century, allowed for better control over the composition of the steel and could handle a wider range of raw materials. Similarly, the basic oxygen process, introduced in the mid-20th century, offered even greater efficiency and flexibility.

Economic Implications

The economic impact of the Bessemer furnace cannot be overstated. By making steel production faster and cheaper, it helped drive the Industrial Revolution and transform the global economy. Industries ranging from construction to transportation benefited from the availability of affordable steel, leading to unprecedented growth and development.

Today, the steel industry remains a vital part of the global economy, contributing billions of dollars in revenue and supporting millions of jobs. The legacy of the Bessemer furnace is evident in the continued importance of steel in modern society.

The Future of Steel Production

As we look to the future, the steel industry faces new challenges and opportunities. With growing concerns about climate change and environmental sustainability, there is a push towards greener and more efficient production methods. Innovations like hydrogen-based steelmaking and carbon capture technology are paving the way for a more sustainable future.

While the Bessemer furnace may no longer be at the forefront of steel production, its impact on the industry and society as a whole is undeniable. As we continue to innovate and evolve, the lessons learned from the Bessemer process will undoubtedly play a role in shaping the future of steel production.

Kesimpulan

And there you have it, folks—a deep dive into the world of the Bessemer furnace. From its humble beginnings in the mid-19th century to its lasting impact on the steel industry, this remarkable invention has truly stood the test of time. It’s a reminder of what human ingenuity can achieve when faced with a challenge.

So, the next time you see a skyscraper, a railway, or a car, take a moment to appreciate the role that the Bessemer furnace played in making them possible. And if you’ve enjoyed this article, don’t forget to leave a comment, share it with your friends, or explore other fascinating topics on our site. Until next time, keep learning and keep innovating!

Detail Author:

- Name : Sherwood Hansen DDS

- Username : alvis48

- Email : aliyah.bernhard@bauch.com

- Birthdate : 1977-10-31

- Address : 43362 Kevon Forest Apt. 707 Greenbury, KY 92207-3833

- Phone : +1.854.961.4403

- Company : Price-Lockman

- Job : Entertainer and Performer

- Bio : Ab odio dolorem nulla ex illum eos. Architecto et ut doloribus occaecati nihil tenetur tempora. Pariatur et est quod commodi error pariatur ducimus.

Socials

tiktok:

- url : https://tiktok.com/@stanton1983

- username : stanton1983

- bio : Consectetur ea inventore molestiae magnam. Quam aut et rem labore.

- followers : 6906

- following : 46

instagram:

- url : https://instagram.com/lessiestanton

- username : lessiestanton

- bio : Odit commodi ea natus qui esse error. Facilis id adipisci expedita omnis totam in optio.

- followers : 2646

- following : 1715

facebook:

- url : https://facebook.com/lstanton

- username : lstanton

- bio : Ullam nihil unde rerum temporibus commodi totam.

- followers : 6911

- following : 2068